Acoustic Flooring Replacement

Our client reported that the previously installed floor finish had reached the end of its service life and required replacement. Following a detailed discussion with the project manager, we gained a clear understanding of their expectations and began planning the new flooring solution.

Client Requirements

The project manager highlighted two key concerns:

Noise reduction – The galley area is located directly outside two double cabins, so improved acoustic performance was essential.

Impact resistance – Breakages of ceramic items in the galley were a frequent issue, requiring a more forgiving flooring surface.

To address these needs, the client opted for a continuous 9mm acoustic flooring system, which offered superior sound absorption and reduced the likelihood of breakages.

Planning & Procurement

Once the specification was agreed, we managed the procurement of all required materials to ensure the project ran smoothly with minimal impact on the crew. As the project was outside Palma, our client selected our Worldwide Site Survey Service to guarantee the best possible outcome from start to finish.

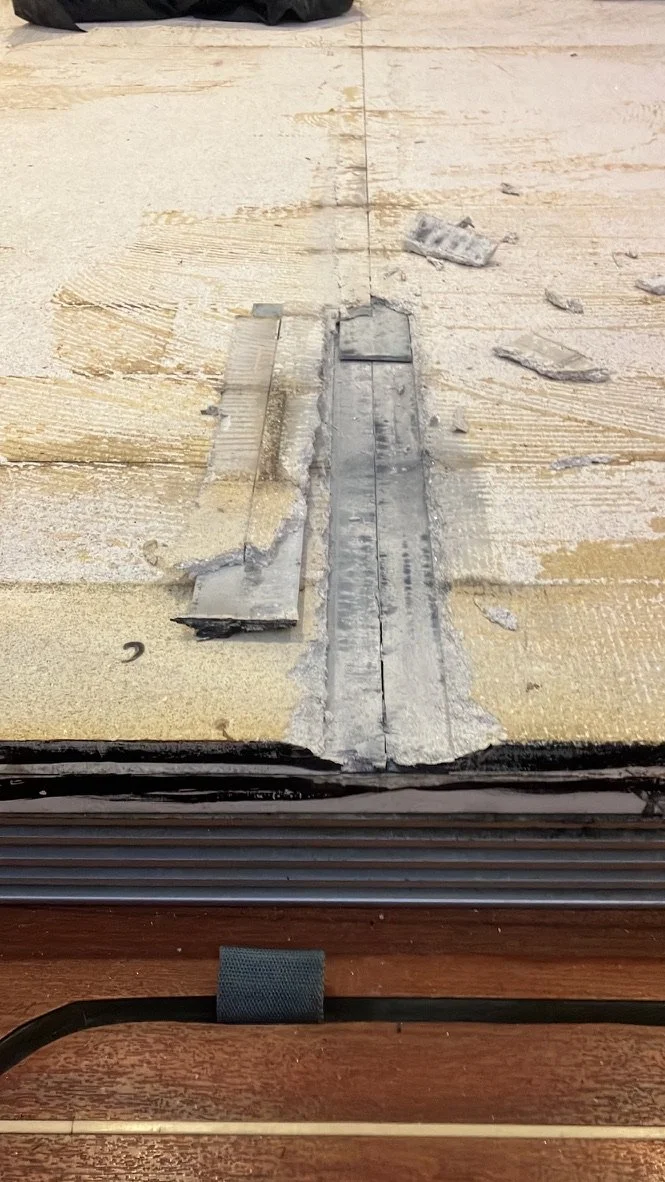

Unforeseen Subfloor Issue

During the initial works, we uncovered a hidden issue: the main subfloor had completely failed. This defect was concealed beneath the old flooring, which had been holding the structure together.

Work was paused while we consulted with the captain and engineering crew. Together, we agreed on a reinforcement strategy:

Cutting back the subfloor in 1m x 1m sections

Accessing the underfloor structure for repairs

Reinforcing the weakened areas before reinstallation

Installation

Once structural repairs were complete, we prepared the area with a suitable primer and applied a high-performance smoothing compound, creating a solid surface for the new vinyl flooring.

We then:

Templated the area with precise measurements.

Cut and shaped the new flooring to millimetre accuracy.

Adhered the vinyl flooring securely to the repaired subfloor.

Installed new stair nosings with R12 slip resistance, protecting crew from slips and trips.

Protected service hatch access, ensuring practicality and safety.

Outcome

The project was completed successfully, delivering a durable, quiet, and resilient flooring system that met all client requirements. Feedback from the captain and project manager was excellent, and we have since been in further discussions with this client about upcoming projects scheduled for later this year and next.

Want to find out more?

Schedule Your Yacht Consultation - Get expert guidance on premium flooring solutions for your vessel. Our specialists understand the unique requirements of marine environments.